- Home

- Science

- Science News

- Scientists Develop Method to Make Cheap Nano Silicon Batteries With Sand

Scientists Develop Method to Make Cheap Nano-Silicon Batteries With Sand

"This is the holy grail a low cost, non-toxic, environmentally friendly way to produce high performance lithium ion battery anodes," said Zachary Favors from University of California, Riverside in the US.

Currently graphite is used in battery anodes, and further improvements on graphite are not viable.

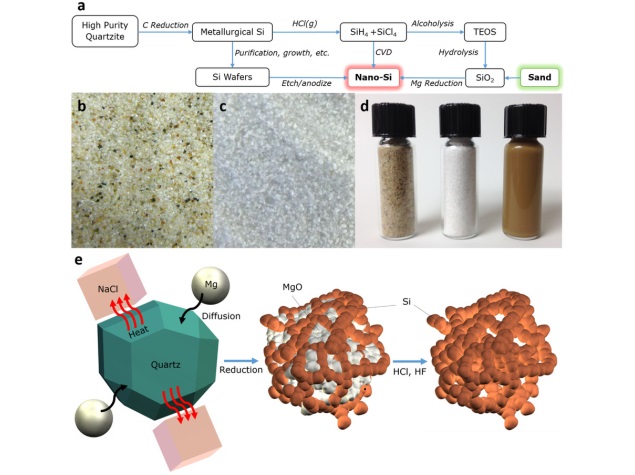

To make better batteries, researchers are focussed on nano silicon, the size of a billionth of a metre, as a replacement for graphite. Nanoscale silicon, however, degrades quickly and is difficult to produce in a large quantity.

To get large quantities, Zachary used the most common source of silica, beach sand from a beach at Cedar Creek.

This pure silicate sand was purified, powdered and then ground with salt and magnesium. This mixture was heated to remove oxygen from the quartz, resulting in pure silicon.

The team was fortunate that the pure nano-silicon formed had a porous three-dimensional silicon sponge like consistency.

That porosity has proved to be the key to improving the performance of the batteries built with the nano-silicon.

The improved performance could mean expanding the expected lifespan of silicon-based batteries up to three times or more.

This better battery could power electric vehicles, cell phones or tablets.

The findings appeared in the journal Nature Scientific Reports.

Catch the latest from the Consumer Electronics Show on Gadgets 360, at our CES 2026 hub.

Related Stories

- Samsung Galaxy Unpacked 2025

- ChatGPT

- Redmi Note 14 Pro+

- iPhone 16

- Apple Vision Pro

- Oneplus 12

- OnePlus Nord CE 3 Lite 5G

- iPhone 13

- Xiaomi 14 Pro

- Oppo Find N3

- Tecno Spark Go (2023)

- Realme V30

- Best Phones Under 25000

- Samsung Galaxy S24 Series

- Cryptocurrency

- iQoo 12

- Samsung Galaxy S24 Ultra

- Giottus

- Samsung Galaxy Z Flip 5

- Apple 'Scary Fast'

- Housefull 5

- GoPro Hero 12 Black Review

- Invincible Season 2

- JioGlass

- HD Ready TV

- Laptop Under 50000

- Smartwatch Under 10000

- Latest Mobile Phones

- Compare Phones

- Vivo Y500i

- OnePlus Turbo 6V

- OnePlus Turbo 6

- Itel Zeno 20 Max

- OPPO Reno 15 Pro Mini 5G

- Poco M8 Pro 5G

- Motorola Signature

- Vivo Y50e 5G

- Lenovo Yoga Slim 7x (2025)

- Lenovo Yoga Slim 7a

- Realme Pad 3

- OPPO Pad Air 5

- Xiaomi Watch 5

- Huawei Watch 10th Anniversary Edition

- Acerpure Nitro Z Series 100-inch QLED TV

- Samsung 43 Inch LED Ultra HD (4K) Smart TV (UA43UE81AFULXL)

- Asus ROG Ally

- Nintendo Switch Lite

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAID5BN-INV)

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAIM5BN-INV)