- Home

- Science

- Science News

- New Self Adaptive Material Heals Itself, Stays Tough: Study

New Self-Adaptive Material Heals Itself, Stays Tough: Study

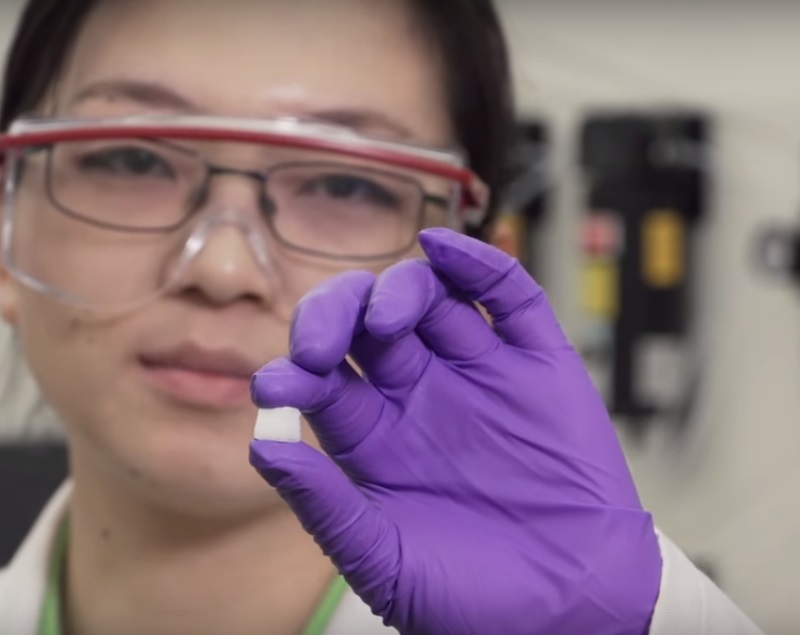

The material created by researchers at Rice University in Texas, US combines self-healing and reversible self-stiffening properties.

Called SAC (self-adaptive composite), the material consists of what amounts to sticky, micron-scale rubber balls that form a solid matrix. The researchers made SAC by mixing two polymers and a solvent that evaporates when heated, leaving a porous mass of gooey spheres.

When cracked, the matrix quickly heals, over and over. Like a sponge, it returns to its original form after compression. Researchers suggest that SAC may be a useful bio-compatible material for tissue engineering or a lightweight, defect-tolerant structural component.

"Other 'self-healing' materials encapsulate liquid in solid shells that leak their healing contents when cracked. Those are very cool, but we wanted to introduce more flexibility," said Pei Dong from Rice University.

"We wanted a biomimetic material that could change itself, or its inner structure, to adapt to external stimulation and thought introducing more liquid would be a way. But we wanted the liquid to be stable instead of flowing everywhere," said Dong.

In SAC, tiny spheres of polyvinylidene fluoride (PVDF) encapsulate much of the liquid. The viscous polydimethylsiloxane (PDMS) further coats the entire surface.

The spheres are extremely resilient as their thin shells deform easily. Their liquid contents enhance their viscoelasticity, a measure of their ability to absorb the strain and return to their original state, while the coatings keep the spheres together. The spheres also have the freedom to slide past each other when compressed, but remain attached.

"The sample does not give you the impression that it contains any liquid. That is very different from a gel," said Lou.

"This is not really squishy; it is more like a sugar cube that you can compress quite a lot. The nice thing is that it recovers," Lou added.

Making SAC is simple, and the process can be tuned - a little more liquid or a little more solid - to regulate the product's mechanical behaviour, researchers said.

The polymer components begin as powder and viscous liquid. With the addition of a solvent and controlled heating, the PDMS stabilises into solid spheres that provide the reconfigurable internal structure.

In tests, scientists found a maximum of 683 percent increase in the material's storage modulus - a size-independent parameter used to characterise self-stiffening behaviour. This is much larger than that reported for solid composites and other materials, researchers said.

The findings were published in the journal ACS Applied Materials and Interfaces.

Catch the latest from the Consumer Electronics Show on Gadgets 360, at our CES 2026 hub.

Related Stories

- Samsung Galaxy Unpacked 2025

- ChatGPT

- Redmi Note 14 Pro+

- iPhone 16

- Apple Vision Pro

- Oneplus 12

- OnePlus Nord CE 3 Lite 5G

- iPhone 13

- Xiaomi 14 Pro

- Oppo Find N3

- Tecno Spark Go (2023)

- Realme V30

- Best Phones Under 25000

- Samsung Galaxy S24 Series

- Cryptocurrency

- iQoo 12

- Samsung Galaxy S24 Ultra

- Giottus

- Samsung Galaxy Z Flip 5

- Apple 'Scary Fast'

- Housefull 5

- GoPro Hero 12 Black Review

- Invincible Season 2

- JioGlass

- HD Ready TV

- Laptop Under 50000

- Smartwatch Under 10000

- Latest Mobile Phones

- Compare Phones

- Tecno Spark Go 3

- iQOO Z11 Turbo

- OPPO A6c

- Samsung Galaxy A07 5G

- Vivo Y500i

- OnePlus Turbo 6V

- OnePlus Turbo 6

- Itel Zeno 20 Max

- Lenovo Yoga Slim 7x (2025)

- Lenovo Yoga Slim 7a

- Realme Pad 3

- OPPO Pad Air 5

- Garmin Quatix 8 Pro

- NoiseFit Pro 6R

- Haier H5E Series

- Acerpure Nitro Z Series 100-inch QLED TV

- Asus ROG Ally

- Nintendo Switch Lite

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAID5BN-INV)

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAIM5BN-INV)

-

Redmi Note 15 Pro, Redmi Note 15 Pro+ 5G India Launch Date Reportedly Leaked

Redmi Note 15 Pro, Redmi Note 15 Pro+ 5G India Launch Date Reportedly Leaked

-

Top Deals on Echo and Fire TV Devices During Amazon Great Republic Day Sale

Top Deals on Echo and Fire TV Devices During Amazon Great Republic Day Sale

-

iPhone Fold, iPhone 18 Pro Series Said to Launch With A20 Pro Chip; Camera and Display Specifications Leaked

iPhone Fold, iPhone 18 Pro Series Said to Launch With A20 Pro Chip; Camera and Display Specifications Leaked

-

MediaTek Announces Dimensity 9500s Flagship Chipset, Rival to Snapdragon 8 Gen 5 and Dimensity 8500 Midrange Chipset

MediaTek Announces Dimensity 9500s Flagship Chipset, Rival to Snapdragon 8 Gen 5 and Dimensity 8500 Midrange Chipset