- Home

- Science

- Science News

- New Fibre Supercapacitor That Can Power Clothing Based Wearables

New Fibre Supercapacitor That Can Power Clothing-Based Wearables

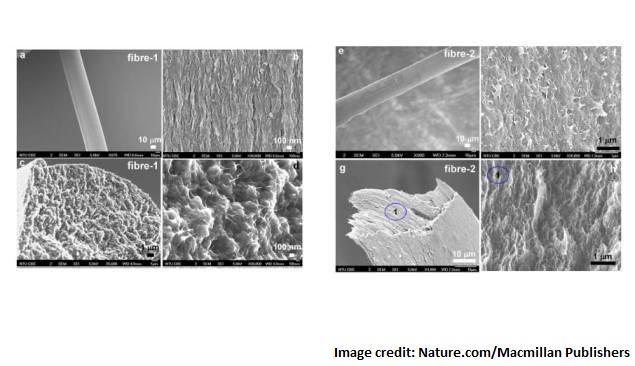

Scientists have developed a supercapacitor that can be woven into clothing to power wearable medical monitors, communications equipment or other small electronics.

The supercapacitor packs an interconnected network of graphene and carbon nanotubes so tightly that it stores energy comparable to some thin-film lithium batteries, researchers said.

The product's developers, engineers and scientists at Nanyang Technological University (NTU) in Singapore, Tsinghua University in China, and Case Western Reserve University in the US, believe the storage capacity by volume (called volumetric energy density) is the highest reported for carbon-based microscale supercapacitors to date: 6.3 microwatt hours per cubic millimetre.

The device also maintains the advantage of charging and releasing energy much faster than a battery. The fibre-structured hybrid materials offer huge accessible surface areas and are highly conductive.

The researchers have developed a way to continuously produce the flexible fibre, enabling them to scale up production for a variety of uses. To date, they've made 50-metre long fibres, and see no limits on length.

They envision the fibre supercapacitor could be woven into clothing to power medical devices for people at home, or communications devices for soldiers in the field. Or, they say, the fibre could be a space-saving power source and serve as "energy-carrying wires" in medical implants.

Liming Dai, a professor of macromolecular science and engineering at Case Western Reserve and a co-author of the paper in Nature Nanotechnology, explained that most supercapacitors have high power density but low energy density, which means they can charge quickly and give a boost of power, but don't last long.

Conversely, batteries have high energy density and low power density, which means they can last a long time, but don't deliver a large amount of energy quickly. To improve the energy density by volume, the researchers designed a hybrid fibre.

A solution containing acid-oxidised single-wall nanotubes, graphene oxide and ethylenediamine, which promotes synthesis and dopes graphene with nitrogen, is pumped through a flexible narrow reinforced tube called a capillary column and heated in an oven for six hours.

Sheets of graphene, one to a few atoms thick, and aligned, single-walled carbon nanotubes self-assemble into an interconnected prorous network that run the length of thefibre.

The arrangement provides huge amounts of accessible surface area - 396 square metres per gram of hybrid fibre - for the transport and storage of charges.

The materials are tightly packed in the capillary column and remain so as they're pumped out, resulting in the high volumetric energy density.For details of the latest launches and news from Samsung, Xiaomi, Realme, OnePlus, Oppo and other companies at the Mobile World Congress in Barcelona, visit our MWC 2026 hub.

- Samsung Galaxy Unpacked 2026

- iPhone 17 Pro Max

- ChatGPT

- iOS 26

- Laptop Under 50000

- Smartwatch Under 10000

- Apple Vision Pro

- Oneplus 12

- OnePlus Nord CE 3 Lite 5G

- iPhone 13

- Xiaomi 14 Pro

- Oppo Find N3

- Tecno Spark Go (2023)

- Realme V30

- Best Phones Under 25000

- Samsung Galaxy S24 Series

- Cryptocurrency

- iQoo 12

- Samsung Galaxy S24 Ultra

- Giottus

- Samsung Galaxy Z Flip 5

- Apple 'Scary Fast'

- Housefull 5

- GoPro Hero 12 Black Review

- Invincible Season 2

- JioGlass

- HD Ready TV

- Latest Mobile Phones

- Compare Phones

- Apple iPhone 17e

- AI+ Pulse 2

- Motorola Razr Fold

- Honor Magic V6

- Leica Leitzphone

- Samsung Galaxy S26+

- Samsung Galaxy S26 Ultra

- Samsung Galaxy S26

- MacBook Pro 16-Inch (M5 Max, 2026)

- MacBook Pro 16-Inch (M5 Pro, 2026)

- Apple iPad Air 13-Inch (2026) Wi-Fi + Cellular

- Apple iPad Air 13-Inch (2026) Wi-Fi

- Huawei Watch GT Runner 2

- Amazfit Active 3 Premium

- Xiaomi QLED TV X Pro 75

- Haier H5E Series

- Asus ROG Ally

- Nintendo Switch Lite

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAID5BN-INV)

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAIM5BN-INV)