- Home

- Science

- Science News

- Low Cost Technique to Produce 'Wonder Material' Graphene Developed

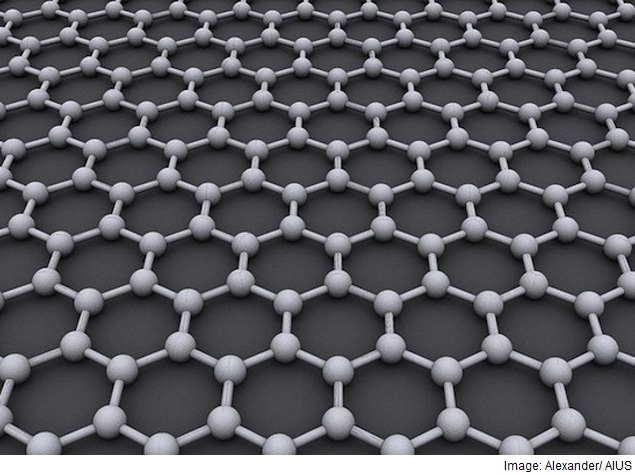

Low-Cost Technique to Produce 'Wonder Material' Graphene Developed

The high-quality graphene can pave the way for development of the first truly flexible "electronic skin" that could be used in robots, the team from University of Exeter reported.

The team, led by professor Monica Craciun, used the new technique to create the first transparent and flexible touch-sensor that could enable the development of artificial skin for use in robot manufacturing.

According to Craciun, the discovery could pave the way for "a graphene-driven industrial revolution" to take place.

The vision for a "graphene-driven industrial revolution" is motivating intensive research on the synthesis of high-quality and low-cost graphene.

Currently, industrial graphene is produced using a technique called Chemical Vapour Deposition (CVD).

The new technique grows graphene in an industrial cold wall CVD system, a state-of-the-art piece of equipment recently developed by UK graphene company Moorfield.

This so-called "nanoCVD system" is based on a concept already used for other manufacturing purposes in the semiconductor industry.

This technique grows graphene 100 times faster than conventional methods, reduces costs by 99 percent and has enhanced electronic quality.

The research team used this new technique to create the first graphene-based transparent and flexible touch sensor.

The sensors can be used not only to create more flexible electronics but also a truly-flexible "electronic skin" that could be used to revolutionise future robots.

The results were published in the leading scientific journal Advanced Materials.

For the latest tech news and reviews, follow Gadgets 360 on X, Facebook, WhatsApp, Threads and Google News. For the latest videos on gadgets and tech, subscribe to our YouTube channel. If you want to know everything about top influencers, follow our in-house Who'sThat360 on Instagram and YouTube.

Related Stories

- Samsung Galaxy Unpacked 2025

- ChatGPT

- Redmi Note 14 Pro+

- iPhone 16

- Apple Vision Pro

- Oneplus 12

- OnePlus Nord CE 3 Lite 5G

- iPhone 13

- Xiaomi 14 Pro

- Oppo Find N3

- Tecno Spark Go (2023)

- Realme V30

- Best Phones Under 25000

- Samsung Galaxy S24 Series

- Cryptocurrency

- iQoo 12

- Samsung Galaxy S24 Ultra

- Giottus

- Samsung Galaxy Z Flip 5

- Apple 'Scary Fast'

- Housefull 5

- GoPro Hero 12 Black Review

- Invincible Season 2

- JioGlass

- HD Ready TV

- Laptop Under 50000

- Smartwatch Under 10000

- Latest Mobile Phones

- Compare Phones

- Moto G15 Power

- Moto G15

- Realme 14x 5G

- Poco M7 Pro 5G

- Poco C75 5G

- Vivo Y300 (China)

- HMD Arc

- Lava Blaze Duo 5G

- Asus Zenbook S 14

- MacBook Pro 16-inch (M4 Max, 2024)

- Honor Pad V9

- Tecno Megapad 11

- Redmi Watch 5

- Huawei Watch Ultimate Design

- Sony 65 Inches Ultra HD (4K) LED Smart TV (KD-65X74L)

- TCL 55 Inches Ultra HD (4K) LED Smart TV (55C61B)

- Sony PlayStation 5 Pro

- Sony PlayStation 5 Slim Digital Edition

- Blue Star 1.5 Ton 3 Star Inverter Split AC (IC318DNUHC)

- Blue Star 1.5 Ton 3 Star Inverter Split AC (IA318VKU)