- Home

- Science

- Science News

- 4D Printing Research Could Pave the Way for Shape Changing Materials

4D Printing Research Could Pave the Way for Shape-Changing Materials

By Press Trust of India | Updated: 26 May 2014 20:36 IST

Click Here to Add Gadgets360 As A Trusted Source

Advertisement

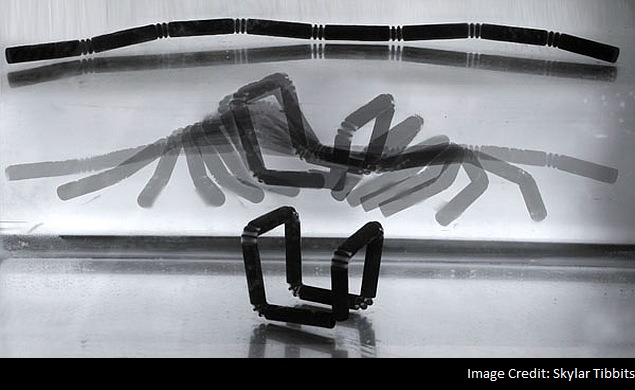

Imagine buying a dress online that changes shape in front of your eyes. Scientists are developing 4D printing technology to pave way for 'smart' materials that can change shape by themselves.

Researchers are combining different types of plastics and fibres to create 'smart' materials that change shape when they come into contact with stimuli such as heat or water.

Objects designed in this way can expand, fold or unfurl into predesigned forms after being printed, in a process dubbed 4D printing.

Skylar Tibbits, from the Massachusetts Institute of Technology, is pioneering the research with Stratasys, a digital manufacturing company.

"We asked if we could print things that change shape and change properties to behave in precise programmed ways. We call it 4D because it adds time [considered the fourth dimension], rather than printing static objects," Tibbits said.

Jesse Louis-Rosenberg, from Nervous System design studio in Somerville, Massachusetts, said he hoped to use 4D printing to create a dress that could be printed in compact form then unfolded.

Using a scan of the customer's body, the dress could be designed to fit perfectly and would be created with a series of tessellating segments.

A computer model would then compress the design into the smallest possible space to fit inside a normal 3D printer. The customer would simply download the design, print it and unfurl it.

Researchers are combining different types of plastics and fibres to create 'smart' materials that change shape when they come into contact with stimuli such as heat or water.

Objects designed in this way can expand, fold or unfurl into predesigned forms after being printed, in a process dubbed 4D printing.

Skylar Tibbits, from the Massachusetts Institute of Technology, is pioneering the research with Stratasys, a digital manufacturing company.

"We asked if we could print things that change shape and change properties to behave in precise programmed ways. We call it 4D because it adds time [considered the fourth dimension], rather than printing static objects," Tibbits said.

Jesse Louis-Rosenberg, from Nervous System design studio in Somerville, Massachusetts, said he hoped to use 4D printing to create a dress that could be printed in compact form then unfolded.

Using a scan of the customer's body, the dress could be designed to fit perfectly and would be created with a series of tessellating segments.

A computer model would then compress the design into the smallest possible space to fit inside a normal 3D printer. The customer would simply download the design, print it and unfurl it.

Comments

For details of the latest launches and news from Samsung, Xiaomi, Realme, OnePlus, Oppo and other companies at the Mobile World Congress in Barcelona, visit our MWC 2026 hub.

Further reading:

3D Printers, 4D Printers, 4D Printind, MIT, Massachusetts Institute of Technology, Printers

Related Stories

Popular on Gadgets

- Samsung Galaxy Unpacked 2026

- iPhone 17 Pro Max

- ChatGPT

- iOS 26

- Laptop Under 50000

- Smartwatch Under 10000

- Apple Vision Pro

- Oneplus 12

- OnePlus Nord CE 3 Lite 5G

- iPhone 13

- Xiaomi 14 Pro

- Oppo Find N3

- Tecno Spark Go (2023)

- Realme V30

- Best Phones Under 25000

- Samsung Galaxy S24 Series

- Cryptocurrency

- iQoo 12

- Samsung Galaxy S24 Ultra

- Giottus

- Samsung Galaxy Z Flip 5

- Apple 'Scary Fast'

- Housefull 5

- GoPro Hero 12 Black Review

- Invincible Season 2

- JioGlass

- HD Ready TV

- Latest Mobile Phones

- Compare Phones

Latest Gadgets

- Apple iPhone 17e

- AI+ Pulse 2

- Motorola Razr Fold

- Honor Magic V6

- Leica Leitzphone

- Samsung Galaxy S26+

- Samsung Galaxy S26 Ultra

- Samsung Galaxy S26

- MacBook Pro 16-Inch (M5 Max, 2026)

- MacBook Pro 16-Inch (M5 Pro, 2026)

- Apple iPad Air 13-Inch (2026) Wi-Fi + Cellular

- Apple iPad Air 13-Inch (2026) Wi-Fi

- Huawei Watch GT Runner 2

- Amazfit Active 3 Premium

- Xiaomi QLED TV X Pro 75

- Haier H5E Series

- Asus ROG Ally

- Nintendo Switch Lite

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAID5BN-INV)

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAIM5BN-INV)

© Copyright Red Pixels Ventures Limited 2026. All rights reserved.