- Home

- Science

- Science News

- 3D Printed Engine Parts Are the Future of Space Launches: Nasa

3D-Printed Engine Parts Are the Future of Space Launches: Nasa

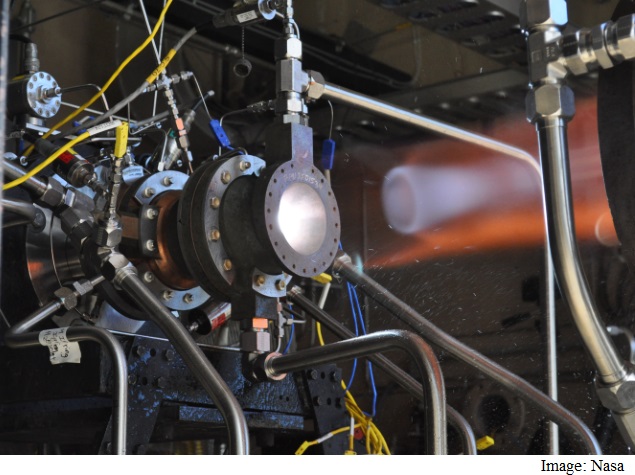

The US space agency and California-based rocket and missile propulsion manufacturer Aerojet Rocketdyne (AR) conducted 19 hot-fire tests on four injector and thrust chamber assembly configurations at Nasa's Glenn Research Centre.

"The successful hot fire test of engine components provides confidence in the additive manufacturing process and paves the way for full-scale development," said Tyler Hickman, lead engineer for the test at Glenn.

3D printing approach is changing the speed, cost and flexibility of designing and building future machines for space and earth applications.

The work is a major milestone in the development and certification of different materials used in the manufacturing process.

Copper alloys offer unique challenges to the additive manufacturing processes.

"Additively manufactured metal propulsion components are truly a paradigm shift for the aerospace industry," added Paul Senick, Glenn project manager.

This will improve efficiency and bring down the cost of space launches and other earth applications, he concluded.

Get your daily dose of tech news, reviews, and insights, in under 80 characters on Gadgets 360 Turbo. Connect with fellow tech lovers on our Forum. Follow us on X, Facebook, WhatsApp, Threads and Google News for instant updates. Catch all the action on our YouTube channel.

Related Stories

- Samsung Galaxy Unpacked 2026

- iPhone 17 Pro Max

- ChatGPT

- iOS 26

- Laptop Under 50000

- Smartwatch Under 10000

- Apple Vision Pro

- Oneplus 12

- OnePlus Nord CE 3 Lite 5G

- iPhone 13

- Xiaomi 14 Pro

- Oppo Find N3

- Tecno Spark Go (2023)

- Realme V30

- Best Phones Under 25000

- Samsung Galaxy S24 Series

- Cryptocurrency

- iQoo 12

- Samsung Galaxy S24 Ultra

- Giottus

- Samsung Galaxy Z Flip 5

- Apple 'Scary Fast'

- Housefull 5

- GoPro Hero 12 Black Review

- Invincible Season 2

- JioGlass

- HD Ready TV

- Latest Mobile Phones

- Compare Phones

- Tecno Pova Curve 2 5G

- Lava Yuva Star 3

- Honor X6d

- OPPO K14x 5G

- Samsung Galaxy F70e 5G

- iQOO 15 Ultra

- OPPO A6v 5G

- OPPO A6i+ 5G

- Asus Vivobook 16 (M1605NAQ)

- Asus Vivobook 15 (2026)

- Brave Ark 2-in-1

- Black Shark Gaming Tablet

- boAt Chrome Iris

- HMD Watch P1

- Haier H5E Series

- Acerpure Nitro Z Series 100-inch QLED TV

- Asus ROG Ally

- Nintendo Switch Lite

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAID5BN-INV)

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAIM5BN-INV)

![[Partner Content] OPPO Reno15 Series: AI Portrait Camera, Popout and First Compact Reno](https://www.gadgets360.com/static/mobile/images/spacer.png)