- Home

- Laptops

- Laptops News

- IBM Unveils World's First 7 Nanometre Chips

IBM Unveils World's First 7-Nanometre Chips

By NDTV Correspondent | Updated: 10 July 2015 10:55 IST

Click Here to Add Gadgets360 As A Trusted Source

Advertisement

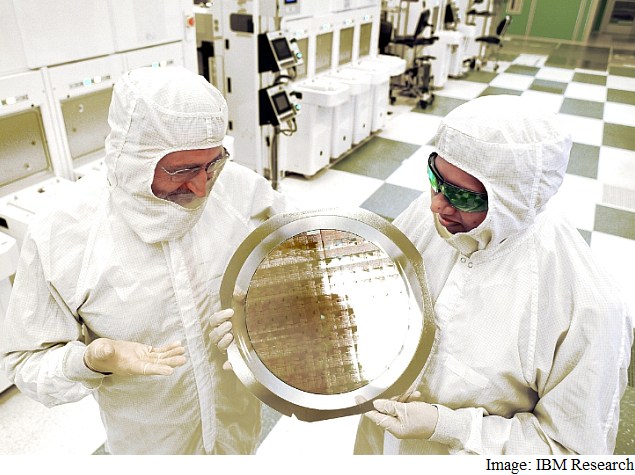

IBM has unveiled the world's first 7nm microprocessor with working transistors, crossing the 10nm barrier in chip design and reaffirming Moore's Law.

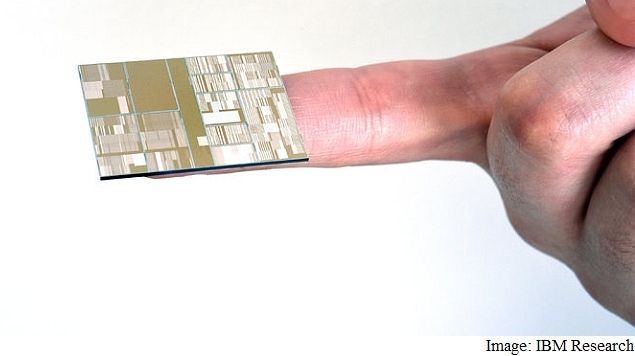

Companies are racing to create smaller, more powerful chips to perform the increasingly complex task that our wired lives demand. At the same time that computer chips have grown more powerful, though, they have also gotten smaller, to the point where you can now hold in your hand a computer many times more powerful than computers that used to fill a room.

Most chips today in PCs and other devices use microprocessors between 14 and 22 nanometres. IBM, working with a development partners at SUNY Polytechnic Institute, says it's figured out how to create 7 nanometre chips. To put that in context, to get to the width of a human hair, you'd need roughly 10,000 of them. A strand of human DNA, in comparison, is 2.5 nanometres.

Made with Common Platform Alliance partners Samsung and GlobalFoundries (which got IBM's chip-making business earlier this year), the 7nm FinFET logic chip design is still in the research phase, and IBM says it will take at least two years to reach commercial production. The estimate shows IBM looks set to leapfrog the cycle, with Intel introducing its first 14nm chips only last year, and its 10nm Cannonlake chips not expected until 2016, at the earliest. Intel has not said anything concrete about its 7nm plans, while TSMC has shared plans to start production on 7nm chips in 2017.

IBM says it has been working on the 7-nanometre transistor fabrication technology for the past five years. It also points to significant jumps in the power-performance ratio, where the new chip can provide comparable performance with greater power efficiency, or greater performance with comparable efficiency. While its 10nm designs improved the ratio by 40-50 percent over 14nm chips, the new 7nm chips push that ratio to 50 percent over 10nm chips.

With 10nm chip designs capable of fitting twice the number of transistors as a 14nm chip, 7nm chips can feature quadruple the number. IBM says with the current working 7nm design it would be possible to fit 20 billion transistors in a microprocessor.

With 10nm chip designs capable of fitting twice the number of transistors as a 14nm chip, 7nm chips can feature quadruple the number. IBM says with the current working 7nm design it would be possible to fit 20 billion transistors in a microprocessor.

IBM says the advances the firm and its allies made to create the smaller, faster chips on the 7nm node include the channel material, as well as the method to etch transistors into the silicon wafer - known as lithography. Switching away from the traditional silicon, IBM used silicon-germanium alloy (SiGe) for its channel transistors to improve electron mobility, allowing them to switch on and off faster.

The company also becomes the first to use the EUV (extreme ultraviolet) photolithography technique to produce a commercially viable design. The technique, which has been looked at to help make sub-10nm chip designs, utilises ultraviolet light with a wavelength of 13.5nm compared to traditional 193nm wavelength of an argon-fluoride laser. Of course, to etch circuits just 7nm wide, the team claims it had to use special masks in conjunction to etch patterns at that scale.

Several industry watchers say it is more than probable IBM has not yet resolved all the problems involved with EUV lithography, and probably hopes to resolve them by 2017. IBM adds it will be much more difficult to advance beyond the 7nm scale, with carbon nanotubes and gallium-arsenide the proposed materials for the jump - the company had tested its first 9nm transistors with carbon nanotube technology back in 2012.

Written with agency inputs

Companies are racing to create smaller, more powerful chips to perform the increasingly complex task that our wired lives demand. At the same time that computer chips have grown more powerful, though, they have also gotten smaller, to the point where you can now hold in your hand a computer many times more powerful than computers that used to fill a room.

Most chips today in PCs and other devices use microprocessors between 14 and 22 nanometres. IBM, working with a development partners at SUNY Polytechnic Institute, says it's figured out how to create 7 nanometre chips. To put that in context, to get to the width of a human hair, you'd need roughly 10,000 of them. A strand of human DNA, in comparison, is 2.5 nanometres.

Made with Common Platform Alliance partners Samsung and GlobalFoundries (which got IBM's chip-making business earlier this year), the 7nm FinFET logic chip design is still in the research phase, and IBM says it will take at least two years to reach commercial production. The estimate shows IBM looks set to leapfrog the cycle, with Intel introducing its first 14nm chips only last year, and its 10nm Cannonlake chips not expected until 2016, at the earliest. Intel has not said anything concrete about its 7nm plans, while TSMC has shared plans to start production on 7nm chips in 2017.

IBM says it has been working on the 7-nanometre transistor fabrication technology for the past five years. It also points to significant jumps in the power-performance ratio, where the new chip can provide comparable performance with greater power efficiency, or greater performance with comparable efficiency. While its 10nm designs improved the ratio by 40-50 percent over 14nm chips, the new 7nm chips push that ratio to 50 percent over 10nm chips.

IBM says the advances the firm and its allies made to create the smaller, faster chips on the 7nm node include the channel material, as well as the method to etch transistors into the silicon wafer - known as lithography. Switching away from the traditional silicon, IBM used silicon-germanium alloy (SiGe) for its channel transistors to improve electron mobility, allowing them to switch on and off faster.

The company also becomes the first to use the EUV (extreme ultraviolet) photolithography technique to produce a commercially viable design. The technique, which has been looked at to help make sub-10nm chip designs, utilises ultraviolet light with a wavelength of 13.5nm compared to traditional 193nm wavelength of an argon-fluoride laser. Of course, to etch circuits just 7nm wide, the team claims it had to use special masks in conjunction to etch patterns at that scale.

Several industry watchers say it is more than probable IBM has not yet resolved all the problems involved with EUV lithography, and probably hopes to resolve them by 2017. IBM adds it will be much more difficult to advance beyond the 7nm scale, with carbon nanotubes and gallium-arsenide the proposed materials for the jump - the company had tested its first 9nm transistors with carbon nanotube technology back in 2012.

Written with agency inputs

Comments

For details of the latest launches and news from Samsung, Xiaomi, Realme, OnePlus, Oppo and other companies at the Mobile World Congress in Barcelona, visit our MWC 2026 hub.

Further reading:

GlobalFoundries, IBM, Intel, Laptops, Moores Law, Samsung, SoC, 7nm chips, Processors

Related Stories

Popular on Gadgets

- Samsung Galaxy Unpacked 2026

- iPhone 17 Pro Max

- ChatGPT

- iOS 26

- Laptop Under 50000

- Smartwatch Under 10000

- Apple Vision Pro

- Oneplus 12

- OnePlus Nord CE 3 Lite 5G

- iPhone 13

- Xiaomi 14 Pro

- Oppo Find N3

- Tecno Spark Go (2023)

- Realme V30

- Best Phones Under 25000

- Samsung Galaxy S24 Series

- Cryptocurrency

- iQoo 12

- Samsung Galaxy S24 Ultra

- Giottus

- Samsung Galaxy Z Flip 5

- Apple 'Scary Fast'

- Housefull 5

- GoPro Hero 12 Black Review

- Invincible Season 2

- JioGlass

- HD Ready TV

- Latest Mobile Phones

- Compare Phones

Latest Gadgets

- Realme C83 5G

- Nothing Phone 4a Pro

- Infinix Note 60 Ultra

- Nothing Phone 4a

- Honor 600 Lite

- Nubia Neo 5 GT

- Realme Narzo Power 5G

- Vivo X300 FE

- MacBook Neo

- MacBook Pro 16-Inch (M5 Max, 2026)

- Tecno Megapad 2

- Apple iPad Air 13-Inch (2026) Wi-Fi + Cellular

- Tecno Watch GT 1S

- Huawei Watch GT Runner 2

- Xiaomi QLED TV X Pro 75

- Haier H5E Series

- Asus ROG Ally

- Nintendo Switch Lite

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAID5BN-INV)

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAIM5BN-INV)

© Copyright Red Pixels Ventures Limited 2026. All rights reserved.